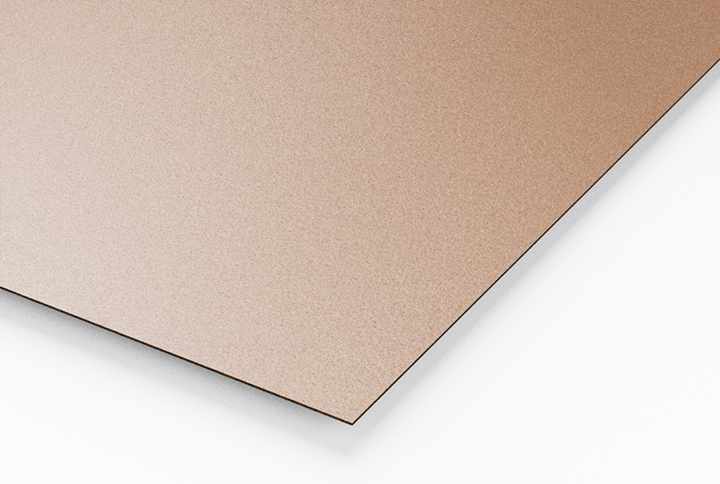

HPL laminate Metallic

Decorative high pressure laminate in postforming quality based on EN 438-8:ATP, with special visual metallic effect thanks to mother-of-pearl pigments. The reverse side is sanded ready for gluing.

Areas of application

-

Furniture construction & interior fitting

Product features

-

Antibacterial

-

Easy care

-

Suitable for contact with food

FORMATS

| Length (mm) | Width (mm) | Thickness (mm) | Textures |

|---|---|---|---|

| 4100 | 1300 | 0,8 | MP |

| 4100 | 1300 | ||

| 2800 | 2070 | ||

| 5600 | 2070 |

Brochures & Certificates

-

Cleaning recommendations Duropal HPL & DecoBoard

PDF (1 MB) -

Environmental Product Declaration (EPD)

-

EPD Background information

PDF (668 KB) -

Information on harmlessness Duropal HPL/Compact

PDF (61 KB) -

Information on the safety data sheet for Pfleiderer products

PDF (37 KB) -

Processing recommendation Film covering of laminates, compact laminates & HPL elements

PDF (874 KB) -

Product Information - Chemical Resistance of Duropal Laminates

PDF (496 KB) -

Product Information - Writability of Duropal HPL / Duropal HPL Magnet

PDF (2 MB) -

ProHPL/ICDLI - Technical Leaflet

PDF (298 KB) -

Technical data Duropal HPL Metallic

PDF (651 KB)

decors

Product processing

- Please respect the recommendations of BLFA (www.blfa.co.uk) an ICDLI (www.icdli.com) for the processing of high pressure laminates.

- For the production of flat-bonded panels we recommend a symmetric construction. This means both sides should be identical HPL. If backing material (also HPL) is used, there is a risk of bowing.

- Sufficient conditioning is required prior to installation and assembly. The premises themselves need to be at the normal climatic conditions in which the material will later be used.

- Especially for large applications, we recommend paying attention to the colour and texture unifomity of the boards and cut products used when further processing and installing and that the production direction is taken into account.

- We recommend carrying out your own tests depending on the respective application and material requirement.

- The material must be stored flat, level and horizontal on clean surfaces at normal climatic conditions (Temperature 18–25 °C, relative humidity 50–65 %).

- Protect from moisture and wet conditions.

- Avoid direct exposure to heat and any possible dehydration of the surfaces by light- or heat radiation or by air currents from heating- or air conditioning systems.

- Avoid exposure to direct sunshine or UV rays, especially of products covered in film.

- The stack must be weighed-down with a cover panel.

- These storage conditions must continue to be ensured after removing panels from the stack.

- Vertical storage is not recommended.

- Please note that incorrect storage, regardless of its duration, may cause irreversible distortion to the sheets.

- Foreign bodies or impurities in the pallet of sheets can lead to impressions and damage to the surface of the board.

- Sheets / boards must not be moved against each other ; they should be moved individually by hand or with suction equipment.

- Ensure that sufficiently large and sturdy bases, e.g. pallets, are used for the transportation of stacked sheets. The sheets on the pallet must be secured against slipping.

- Please wear the appropriate personal protective equipment (PPE) when processing and handling.

- Provide adequate extraction when splitting/sanding.

- The surface can be cleaned with water and gentle cleaning agents. To remove stubborn stains, please observe the recommendations in the data sheet "Cleaning of HPL surfaces" (www.icdli.com).

- Energy recovery in industrial furnaces at temperatures above 700 °C.

Processing

Storage, handling and transport

Health and safety

Cleaning and care

Disposal

Watch video